Manufacturing

Manufacturing

Core Configuration and Advantages:

01

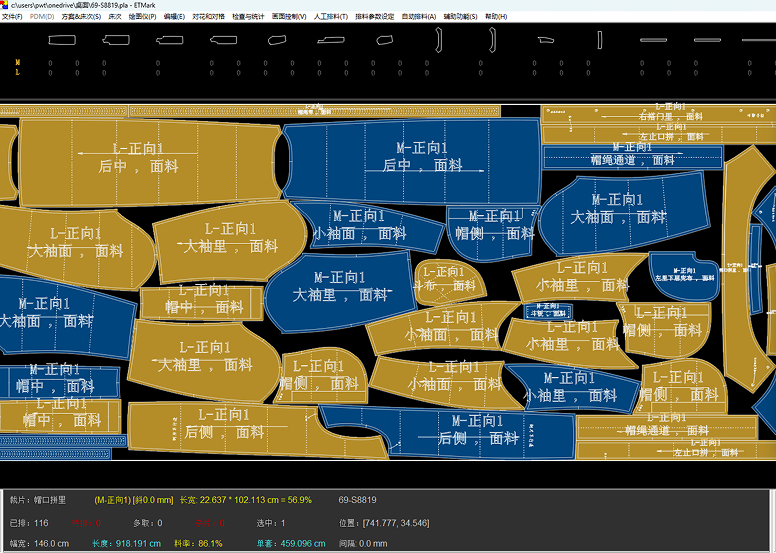

High-Precision Automatic Cutting Bed + Intelligent Nesting System

We utilize computer-controlled automatic cutting beds that precisely cut multiple layers of fabric, significantly improving material utilization and cutting accuracy. The intelligent nesting system optimizes marker plans, reducing waste from the source.

02

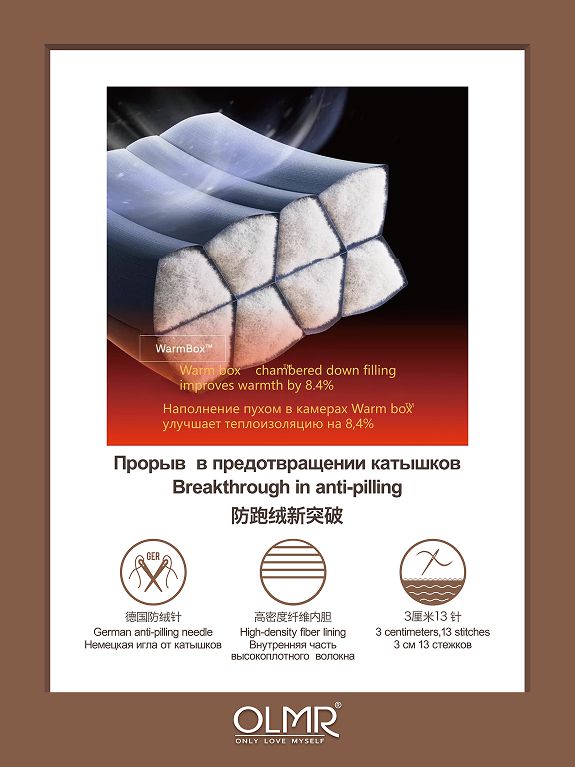

Semi-Automatic Template Sewing and Precision Down Filling

· Template Sewing Machines: Widely used for key processes such as pockets, zipper installation, and quilting, ensuring uniform stitches and significantly enhancing product standardization and aesthetics.

· Computerized Down Filling Machines: This is our core equipment. It fills each garment compartment independently with high precision of 0.1 grams, guaranteeing accurate down fill weight for each finished product and ensuring stable and reliable thermal performance.

03

Professional Finishing and Strict Quality Inspection

· Efficient Ironing Equipment: Ensures the finished product is smooth and sharp, and helps to fluff up the down.

· High-Sensitivity Metal Detectors: 100% full inspection ensures product safety without any metal residues, complying with international safety standards.

· Vacuum Packaging System: Reduces storage and shipping volume, lowering logistics costs.

Craftsmanship Process:

Manufacturing Excellence:

We operate a self-owned, modern production base equipped with industry-leading specialized down jacket manufacturing facilities. Through lean production management, our annual capacity exceeds 1 million pieces, ensuring each down jacket meets stringent quality standards.

RELATED PRODUCTS

Navigation

Navigation

Contact Details

Send Inquiry

Send Inquiry